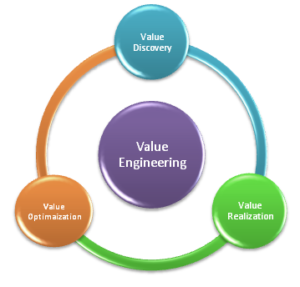

If you are not the proud owner of some type of management or engineering degree, then chances are that you may not be overly familiar with the term value engineering. Value engineering is often referred to as “VE” options in the architectural, engineering, and construction world. When someone refers to providing Value engineering options, they are attempting to optimize the project to the owner’s specifications at the lowest price possible.

Companies encourage creative strategies in regards to cost from the initial design to its eventual disposal in an attempt to achieve the lowest life-cycle cost available for the project. Then they look at any cost-saving alternatives that can be employed during the project. Alternates can include analysis on things such as materials, equipment, facilities, systems, and services used in the project. This part of project management requires an analysis to be performed on each of these components. The goal is to reduce the price without reducing the quality of the end product. Reducing the overall timeline, decreasing expenses, using existing resources more efficiently, and improving product quality are all methods utilized in the process.

“Value engineering is the process where we add value to our owners by finding ways to save our clients’ money through design options, decreasing the cost, or changes in scope on one of our projects.” – Jim Cooper | Vice-President

Advantages of Value Engineering

Advantages of Value Engineering

- Establishes Clear Expectations / Prevents Confusion

- Reduced Time to Substantial Completion

- Customized instead of one-size-fits-all systems and solutions

- Reduced Materials and Labor Cost

- Can reduce the overall operational cost of a facility for years to come

- Reduce carbon footprint – more energy efficient systems

The problem with value engineering is that for some people who are not well connected to the AEC industry the word “Value Engineering” has a negative connotation. Some people use the phrase to describe the process and removing the elements of design that make a project unique and visually appealing. Others use the term to describe a project as cheaply built. However, none of those things are true with a project that uses VE principles correctly.

Overcoming Misconceptions of Value Engineering

- It’s not about cost-cutting, it’s about prioritizing goals

- Waiting until the Construction Phase will reduce the opportunity for VE and delay the project. Start using VE options during the preconstruction process to maximize the “bang for your buck”

- Significant Cost Savings are often in found in initial systems such as mechanical, electrical, and plumbing installations — not furniture, fixtures, and equipment.

- Waiting until late in the process for fixtures such as lighting can actually cost you money because of lead times.

- Value engineering doesn’t stifle creativity, it invigorates it! Using creativity can often leave an owner with more choices and not less in the final look and feel of a project.

Recent Real Examples of Value Engineering

- HVAC System Components

- Electrical System Components

- Exterior Finishes (i.e., Brick, Stucco, Stone Costs) Lighting Fixtures (i.e. Lifetime Green Savings) Roof Type Materials

- Store Front Sizing and Selection

- Utility Sizes for Exterior Selections

- Utilizing EIFS

- Asphalt Layout

- Material Selections for Storm & Utility Pipes/Drains

“Through Value engineering options we recently saved the Habersham County Board of Commissioners $100,000 which allowed us to add back 1.6% to their contingency to aide in providing the owner options while staying within budget.” – Todd Davis | Director of PreConstruction Services

Rules to Maximize the Results of Value Engineering

Lawrence Miles, who worked for the General Electric Company in the USA during the Second World War, is considered the father of the Value Engineering strategy. He was responsible for keeping things running during a time when labor and material were in short supply. Miles was responsible for purchasing raw materials and realized if he was unable to obtain one particular material, then it was necessary to obtain a replacement material which performed the same function. So, he developed the following criteria to accelerate his end results while maintaining quality.

- Avoid generalities

- Get all available costs

- Use information from the best source

- Blast, create and refine

- Be creative

- Identify and overcome roadblocks

- Use industry experts

- Price key tolerances

- Use standard products

- Use (and pay for) expert advice

- Use specialists’ processes

Putting Value Engineering to Work in Your Project

In order for the VE Process to be successful, the project manager must take a pro-active role in both giving direction and leadership in the value engineering process. They must also ensure that time and effort is not wasted and does not have a detrimental effect on the progress of the project. Value engineering can go a long way in truly providing the customer with a project they can be proud of when all of the team members are truly committed to success.

Cooper and Company offers preconstruction and value engineering services to all of our clients. If you have any questions or would like more information on the process and strategy behind value engineering your upcoming project — just reach out to us for more information.